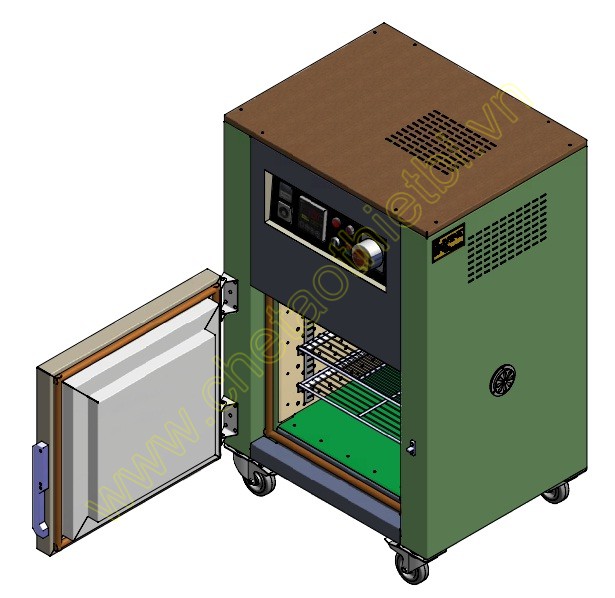

Applications

The divert seat valve is a kind of hygienic pneumatic single seat valve, which is widely applied to the food-processing ,beverage,pharmaceutical

and fine chemical industries.

Working principle:

Seat valves are operated automatically by a single-acting or a double-acting pneumatic actuator. By supplying compressed air, the shaft is moved to turn valve to the "on" or "off" position.

The 180°rotation of the pneumatic cylinder can make normally open and normally closed interchangeable.

| Design and features: - Compact and robust design. 3A certified. - Available sizes: from DN 25/1" to DN 100/4". - Normally closed valve (NC) is the standard version. - The valve can be changed to normally open (NO) by simply reversing the position of the pneumatic actuator. - Hygienic design according to 3A standards. - 360° adjustable body. - Open window allows visual inspection of the shaft sealing. - Easily assemble/disassemble the internal parts by loosening the clamp. - Welded connections (mm or inches). |

.jpg) |

|

Materials |

|

Recommended configuration

- Double-acting pneumatic actuator.

- "Twin-Stop" actuator.

- External position sensors.

- Steam barrier (if shaft sterilisation is required).

- Jacketed body.

- C-TOP control unit.

- Surface finish: Ra ≤ 0,5 μm

- Manual actuation.

- Material and roughness certificates.

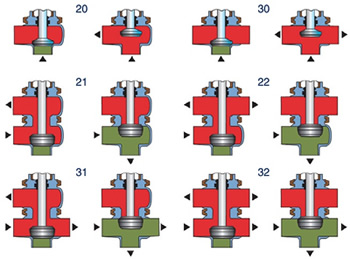

Operating principle:

- The valve body combination is also suitable for the divert seat valve manually.

- The valve body combination with 20 type and 30 type is single-seat valve.

- The valve body combination with 21 type,22 type, 31 type and 32 type is double-seat valve.

Below combination it is reference for diagram of fluid.

Hotline.

Ms. Vân Anh - 0904883101

.jpg)