|

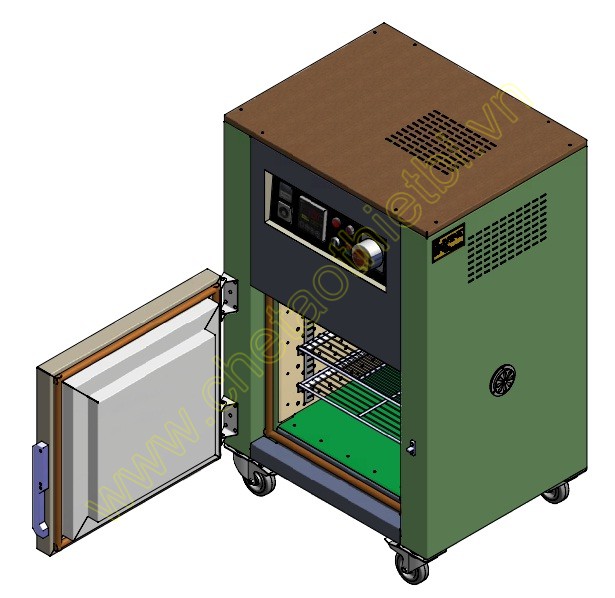

Applications Operating Principle ZH4 sanitary check valve has two configurations. ZH4-1 sanitary check valve adopts clamp connection method. It is affordable and widely used in food industry. ZH4-2 sanitary check valve consists of a thickened valve body and two flanges, which is easy to install and remove. |

|

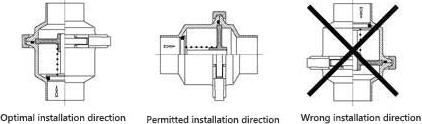

Correct Installation Method

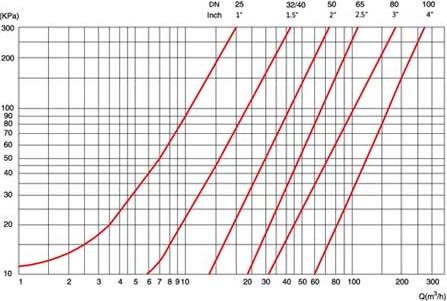

Pressure Drop/Capacity Comparison Diagram

Technical Data

|

Metal material |

Product wetted |

304L/316L (DIN-1.4307/1.4404) forged |

|

Non-product wetted |

304 (DIN-1.4301) |

|

|

We can provide EN 10204 3.1B certificate. |

||

|

Seal material |

Standard |

EPDM |

|

Options |

NBR, FPM, Silicone |

|

|

All seal materials comply with FDA 177.2600. |

||

|

Temperature |

Continuous working temperature |

-20°C ~ +135°C (EPDM) |

|

Sterilization temperature |

150°C (Max 20min) |

|

|

Pressure |

Opening pressure |

0.08bar |

|

Max working pressure |

10bar |

|

|

Surface treatment |

Internal surface |

Ra≤0.8µm |

|

External surface |

Ra≤1.6µm |

|

|

Connection |

Connection standards |

Welding end: DIN 11850 series 2 |

|

Welding end: Inch pipe diameter standard |

||

|

Connection methods: welding, thread, clamp, flange |

||

Hotline.

Ms. Vân Anh - 0904883101

.jpg)