|

Applications HY2-1 sanitary constant pressure valve maintains a constant pressure at the inlet port of the valve in the process pipe. It is used at the rear of separators, heat exchangers, and used as an overflow valve. HY2-2 sanitary constant pressure valve maintains a constant pressure at the outlet port of the valve in the process pipe. It is used at the front of filling or bottling machines. |

|

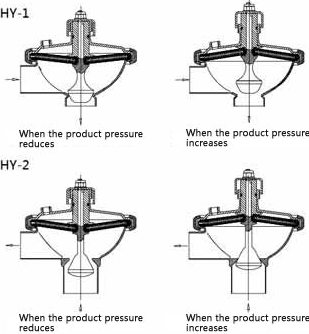

Operating Principle

HY2 sanitary constant pressure valve is remotely controlled by means of compressed air. The valve can be operated without a transmitter and requires only a pressure regulating valve for the compressed air and a pressure gauge in the product line. A diaphragm/valve stem system can quickly response to any pressure changes of the delivery products, and change the valve stem position accordingly in order to maintain the default pressure value.

HY2-1 sanitary constant pressure valve is open when the product pressure increases and vice versa. HY2-2 sanitary constant pressure valve is closed when the product pressure increases and vice versa. (The operating principle is shown as follows.)

Working Conditions

Technical Data

|

Metal material |

Product wetted |

316L (DIN-1.4404) |

|

Non-product wetted |

304 (DIN-1.4301) |

|

|

We can provide EN 10204 3.1B certificate. |

||

|

Seal material |

Standard |

PTFE coated EPDM rubber |

|

All sealing materials comply with FDA 177.2600. |

||

|

Temperature |

Continuous working temperature |

-20°C ~ +135°C |

|

Sterilization temperature |

150°C (Max 20min) |

|

|

Pressure |

Working pressure |

0~10bar |

|

Surface treatment |

Internal surface |

Ra≤0.8µm |

|

External surface |

Shot blasting |

|

|

Connection |

Connection standards |

Welding end: DIN 11850 series 2 |

|

Welding end: Inch pipe diameter standard |

||

|

Connection methods: welding, thread, clamp |

||

Hotline.

Ms. Vân Anh - 0904883101

.jpg)