|

Series DMTFW-E Flanged Ultrasonic Energy Meter

Series DMTFW-E flanged ultrasonic energy meter features State-of-the-Art transit time digital signal processing.

The streamlined, rugged construction ensures high reliability, good stability and high accuracy in all industrial environments.

This self-contained meter has no moving parts and does not require external power to operate the transmitter display. The self contained battery has a life of over 6 yeas*. An optional externally power supply for 4-20mA, RS232/485 output is available. It utilizes a pair of temperature transmitter for energy measurement function. The meters come completely configured from the factory and the only thing left to do is to install them and take readings. The meters have the same to face to face dimensions as industrial water meters making them completely interchangeable.

Features

● Integral transmitter suitable for harsh environments.

● High measurements precision, high accuracy 0.1 deg C

● Low maintenance no moving parts or flow obstructions translates into long-term stability.

● Very low minimum measurable flow velocity (0.003m/s).

● Self-adjusting transducer receiving circuit continually adapts for changing pipe parameters such as scaling or corrosion.

● Fast response to flow transients, tracks flow rate changes better than electromagnetic meters.

● Available with optional infrared meter reading function (AMR).

● DC or Battery powered operates for over 6 years*.

● Unique housing design, rated to IP68.

● Flange /body formed as one integrated piece reduces possibility of leakage.

● On-board self-diagnostic function and fault indicator.

Benefits

● High measurements precision.

● Long-term stability & accuracy over a wide range of conditions.

● High reliability and minimum maintenance requirements.

● Maintenance-free meter where no external power sources are available.

● Communications port permits transfer of data from remote stations to central HMI.

Applications

● Process control and instrumentation.

● Energy measurement.

● Replacing high maintenance mechanical flow meters.

● Measure instantaneous and total flow rates in water networks.

Technical Parameters

|

Item

|

Description

|

|

Accuracy

|

Class 2

|

|

Linearity

|

+/-1.0% of accuracy (when velocity no less than 0.3m/s)

|

|

Repeatability

|

Better than 0.2% (R)

|

|

Sensitivity/Dead band

|

0.0003m/s

|

|

Actual Turndown Ratio

|

20:1 (Operable turndown~3000:1)

|

|

LCD display

|

Automatic circulative display heat flow rate and total heat flow

|

|

Display version

|

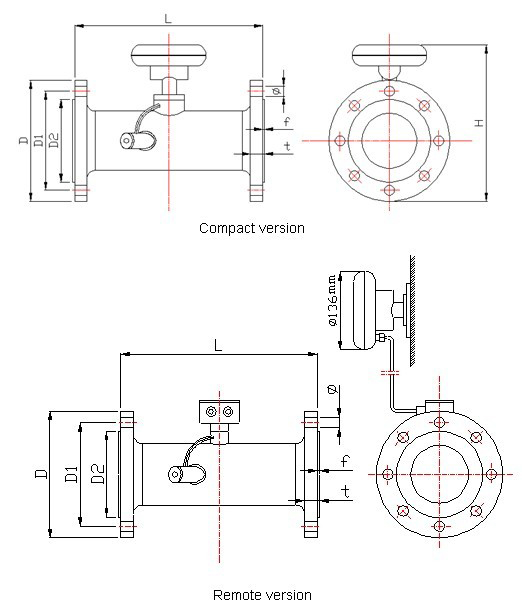

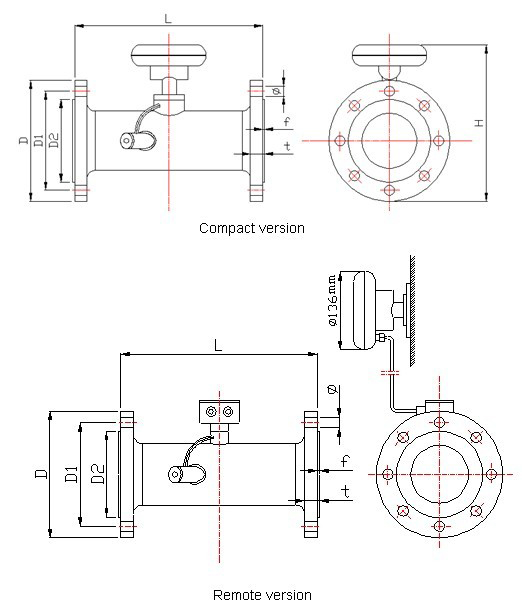

Compact type as standard. Distributed version also available, max. calble length 10m.

|

|

Positive, Negative Flow Totals

|

Bi-directional flow totalizer (+ and -)

|

|

Output

|

4~20mA output (Optional)

|

|

pulse (open-collector output)

|

|

Data interface (Optional)

|

RS232,RS485,M-Bus,ModBus,Infrared data reading, and GPRS wireless module

|

|

Data logger

|

Maintains data history (i.e. totalizer values, workigntime etc.) for up to 35 months Data is automatically saved if power supply is cut.

|

|

Power Supply

|

High power lithium battery(6 yrs life), 9~30VDC required for output options (i.e. 4-20mA, RS232/485, ModBus, M-Bus, GPRS wireless module).

|

|

Velocity range

|

0.01~32.00m/s

|

|

Ambient temperature limit

|

0℃~65℃ (for meter)

|

|

Process temperature fluid

|

(4F~302F)

|

|

Max. Pressure Rating

|

1.6MPa (232PSI)

|

|

Ingress Protection

|

IP68, submersible indefinitely to 10m (30feet)

|

|

Flange standard

|

Flanges according to DIN (EN 1092-1), ANSI(B16.5), JIN standards.

|

|