|

Applications

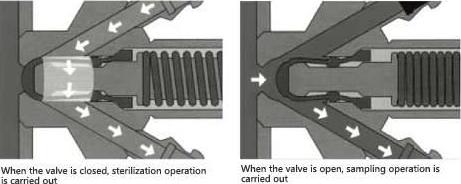

Sampling: Sterilization after valve is closed:

|

|

The maximum sterilization temperature (seal material: EPDM) for dry steam (2-3bar) is 135°C -150°C, with a time limit of less than 20min. The steam must be dry, because the condensation water may damage the diaphragm. We suggest that you should replace the diaphragms after every 100 sampling operations or sterilization operations, or you can replace them according to your experience or working conditions.

PW aseptic sampling valve have two configurations.

PW-1 type is manually operated with fast-open structure. It consists of a valve body, a valve head, a handle, and a diaphragm. Rubber diaphragm is placed in the shaft core of the valve head, and used as a ductile valve core. The valve body and valve head are both replaceable.

PW-2 type is manually or pneumatically operated with fast-open structure. It consists of a valve body, a valve head, an actuator, and a diaphragm. Rubber diaphragm is placed in the shaft of the valve head, and used as a ductile valve core. The majority of manual and pneumatic components are replaceable, and pneumatic valve can be equipped with a fast-open handle.

Working Conditions

Technical Data

|

Metal material |

Product wetted |

316L (DIN-1.4404) |

|

Non-product wetted |

304 (DIN-1.4301) |

|

|

We can provide EN 10204 3.1B certificate. |

||

|

Seal material |

Standard |

EPDM |

|

Options |

Silicone, FPM, PTFE |

|

|

All seal materials comply with FDA 177.2600. |

||

|

Temperature |

Continuous working temperature |

-20°C ~ +135°C (EPDM) |

|

Sterilization temperature |

150°C (Max 20min) |

|

|

Pressure |

Working pressure |

≈10bar |

|

Control air pressure |

5~8bar |

|

|

Surface treatment |

Internal surface |

Ra≤0.8µm |

|

External surface |

Shot blasting |

|

|

Connection |

Connection methods: welding, thread, clamp |

|

Hotline.

Ms. Vân Anh - 0904883101

.jpg)